Precast Colors and Finishes

Examples of Colors & Finishes

Finishes and Textures

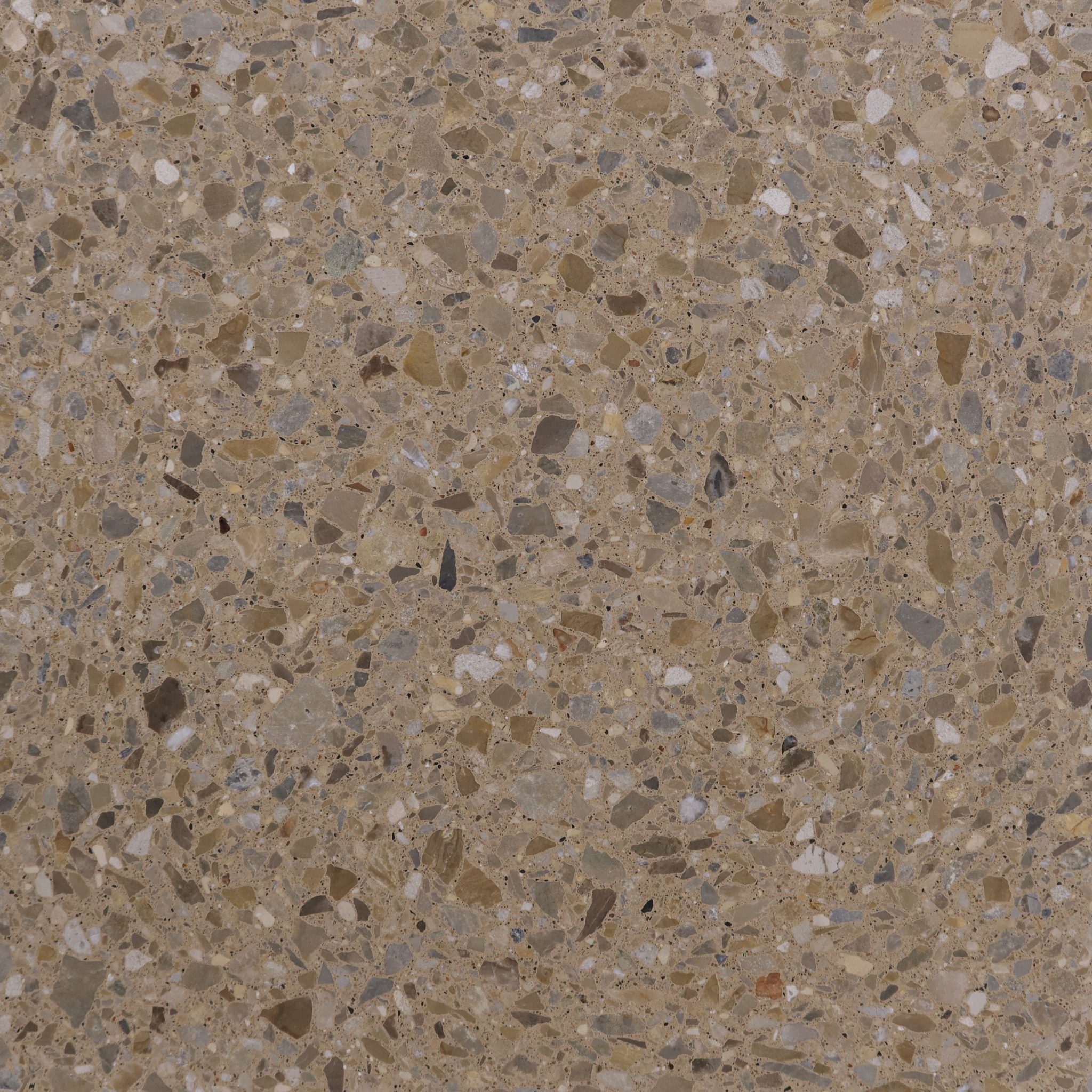

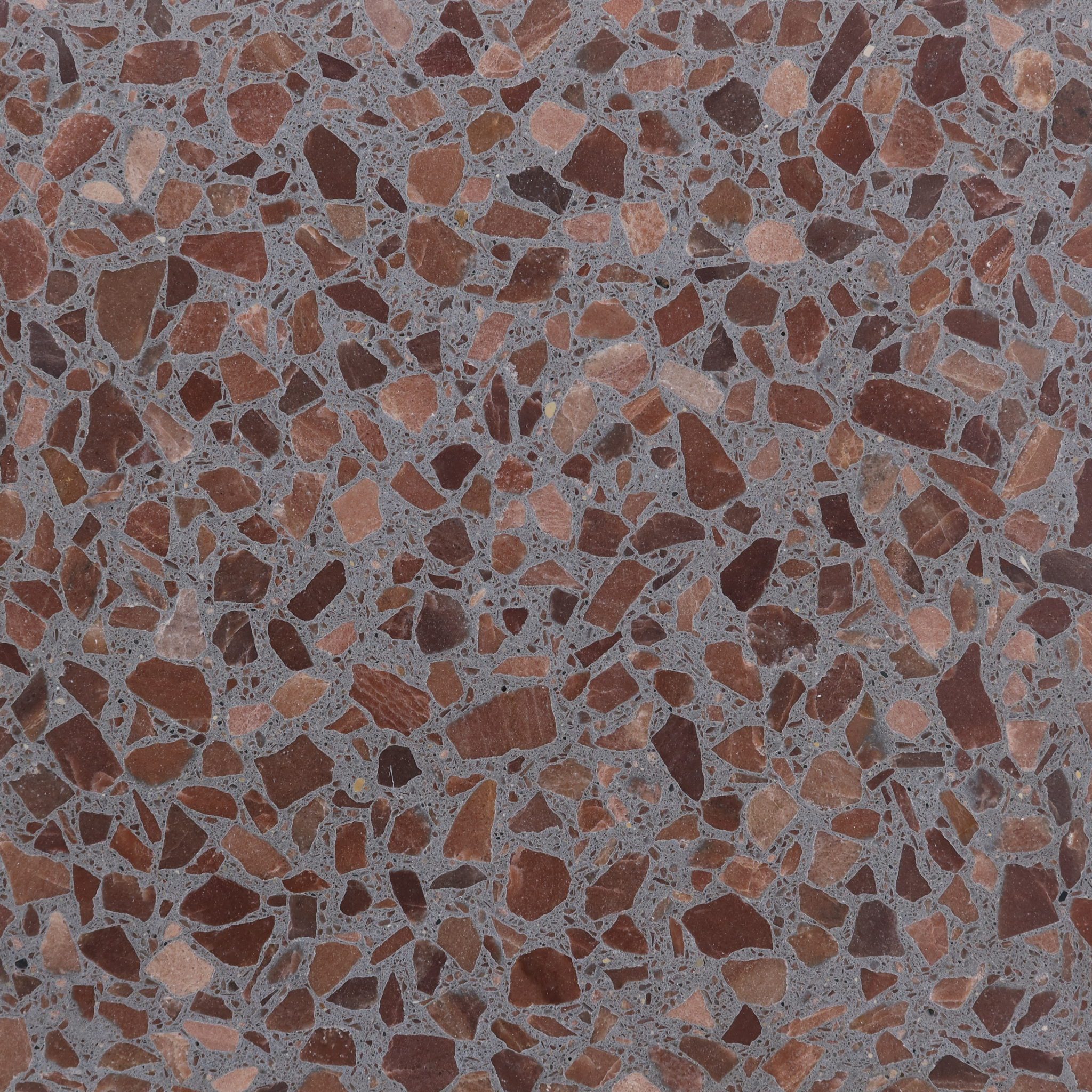

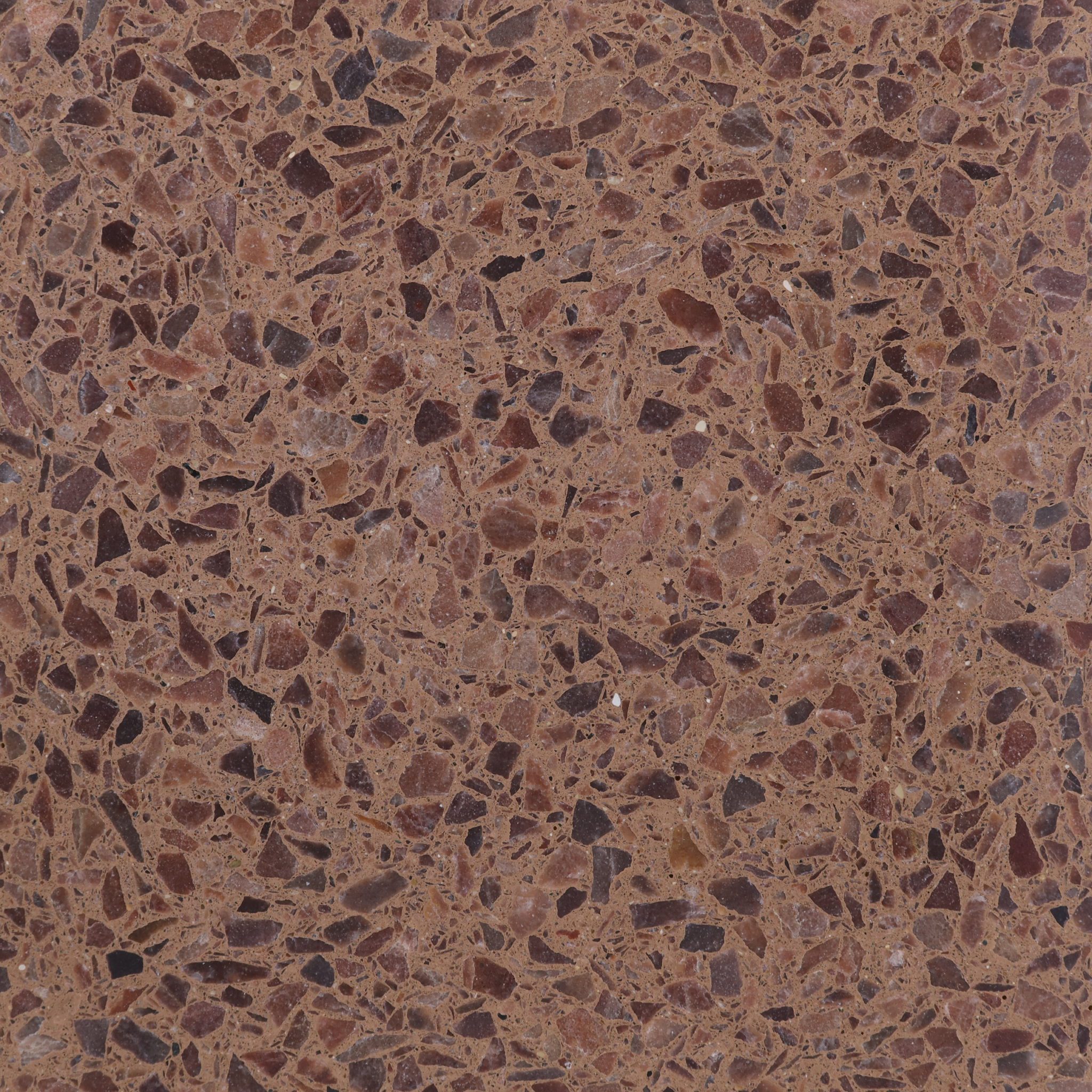

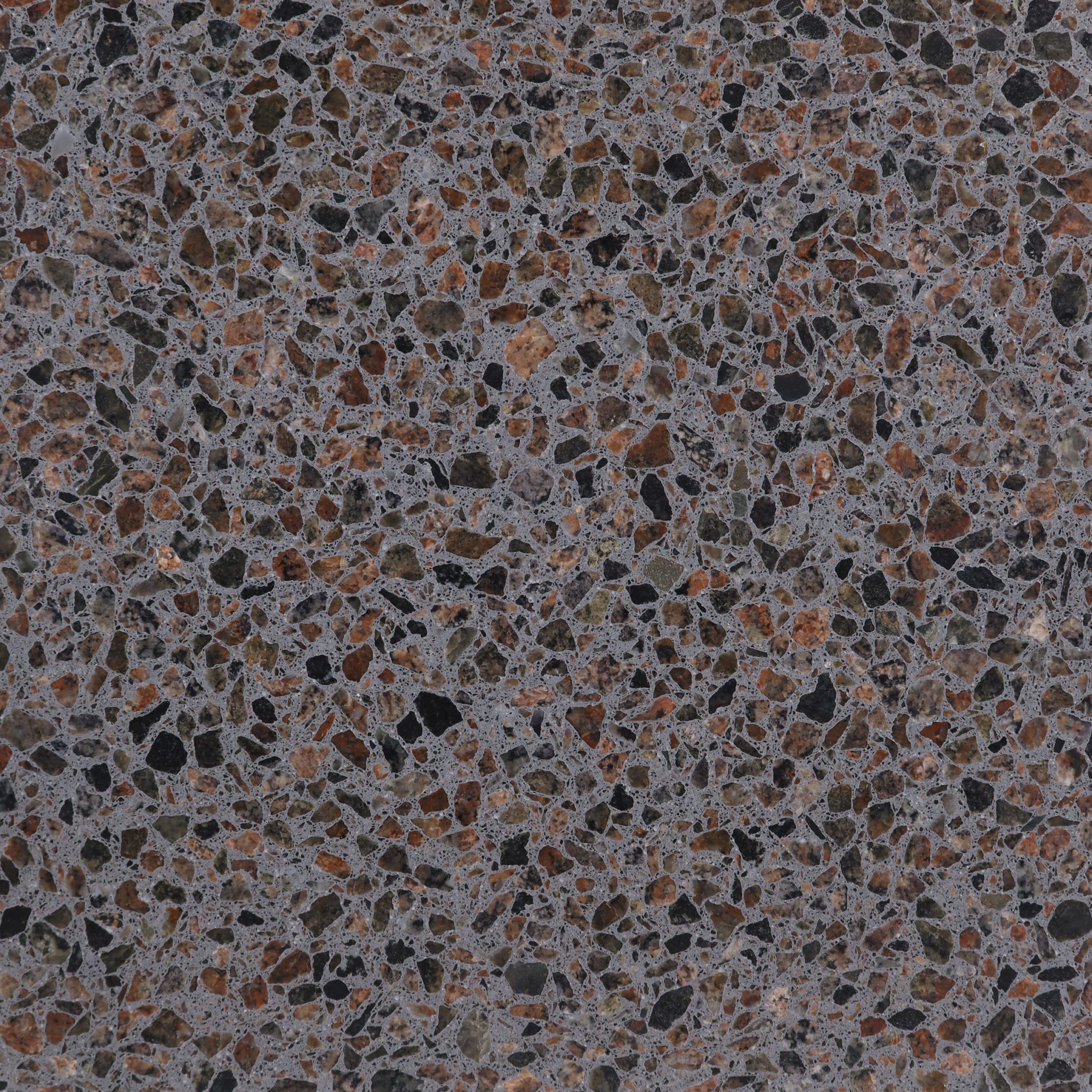

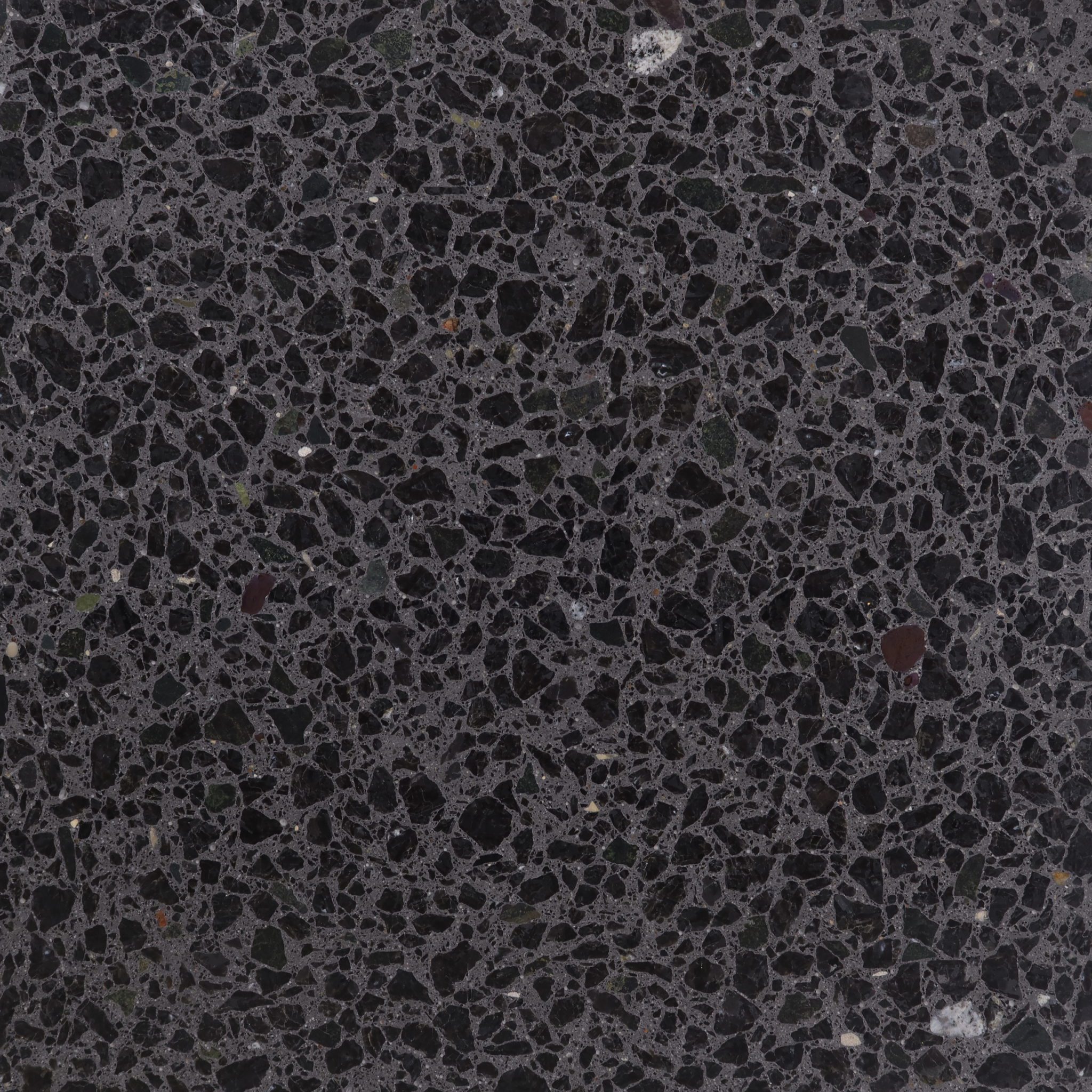

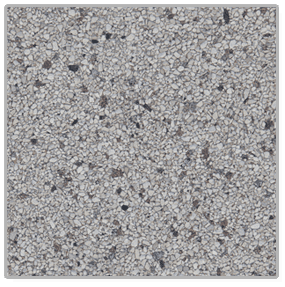

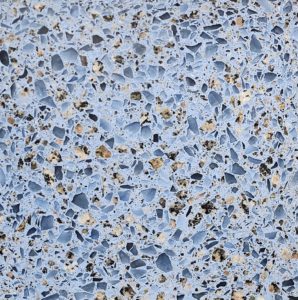

Polished

This process uses a series of diamond grinding wheels to polish the surface. This results in exposure of the aggregate with a smooth polished finish similar to polished granite.

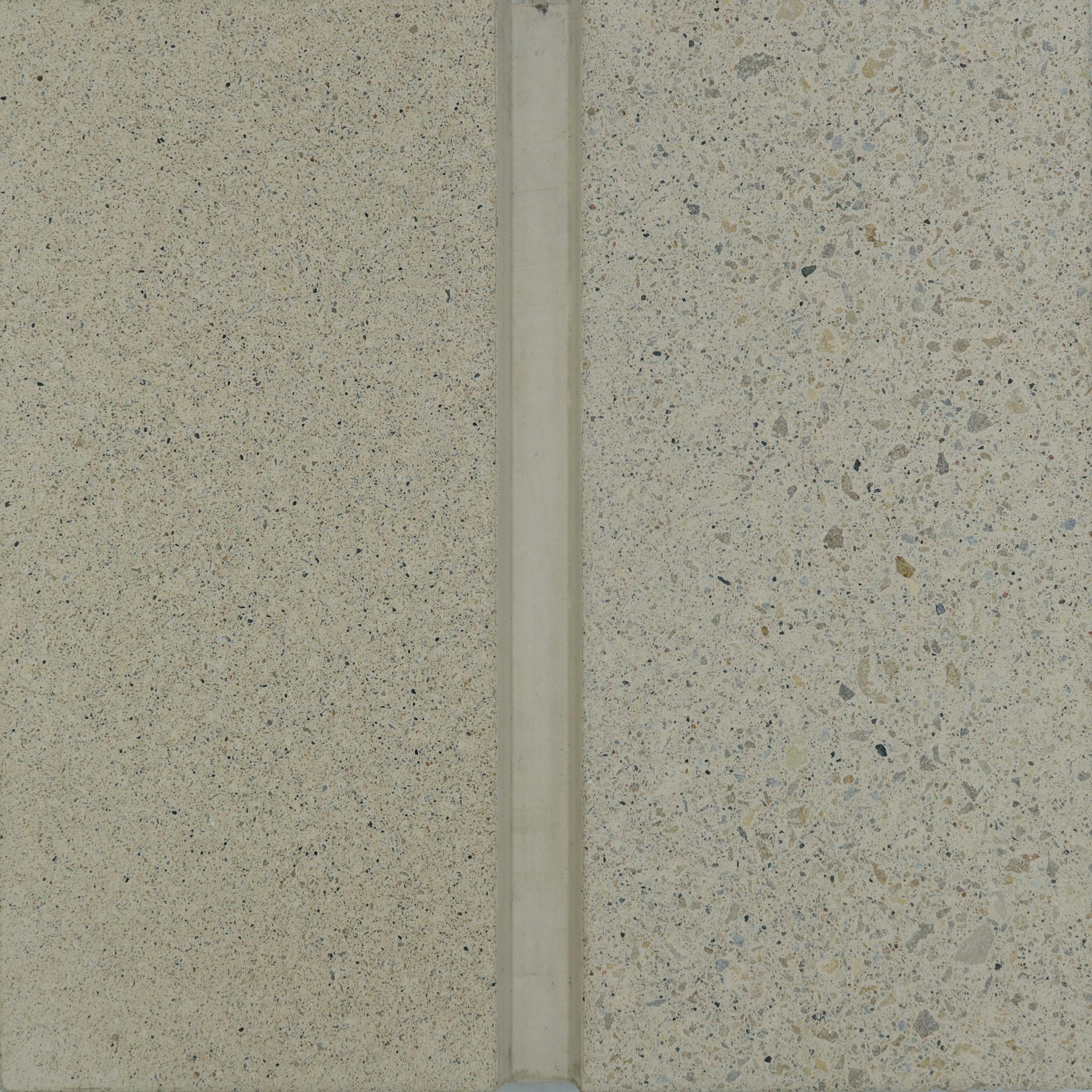

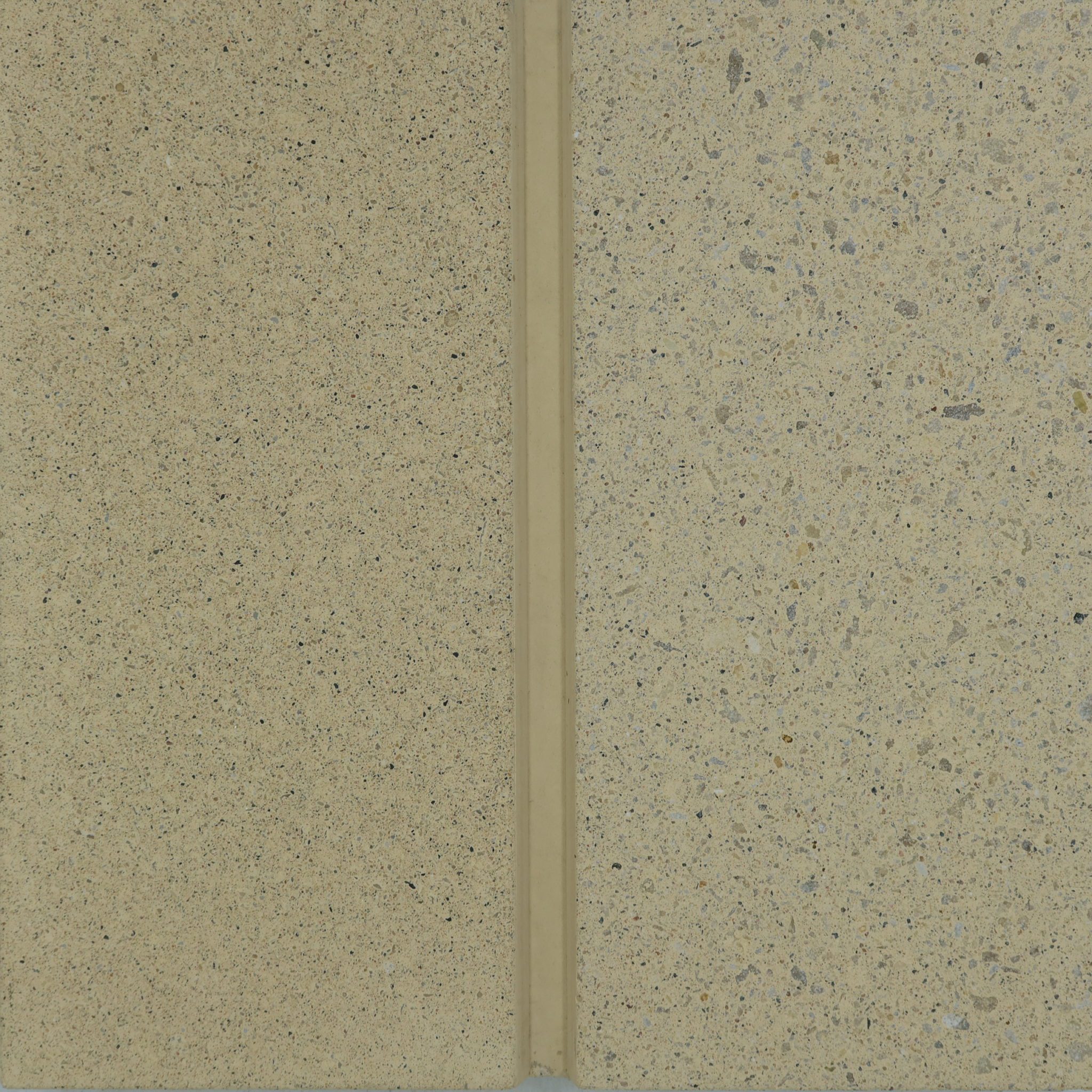

Acid Etched

This process uses acid with high pressure water to etch the surface of the concrete. This usually darkens the finish and leaves a sparkle or “sugar-cube” effect.

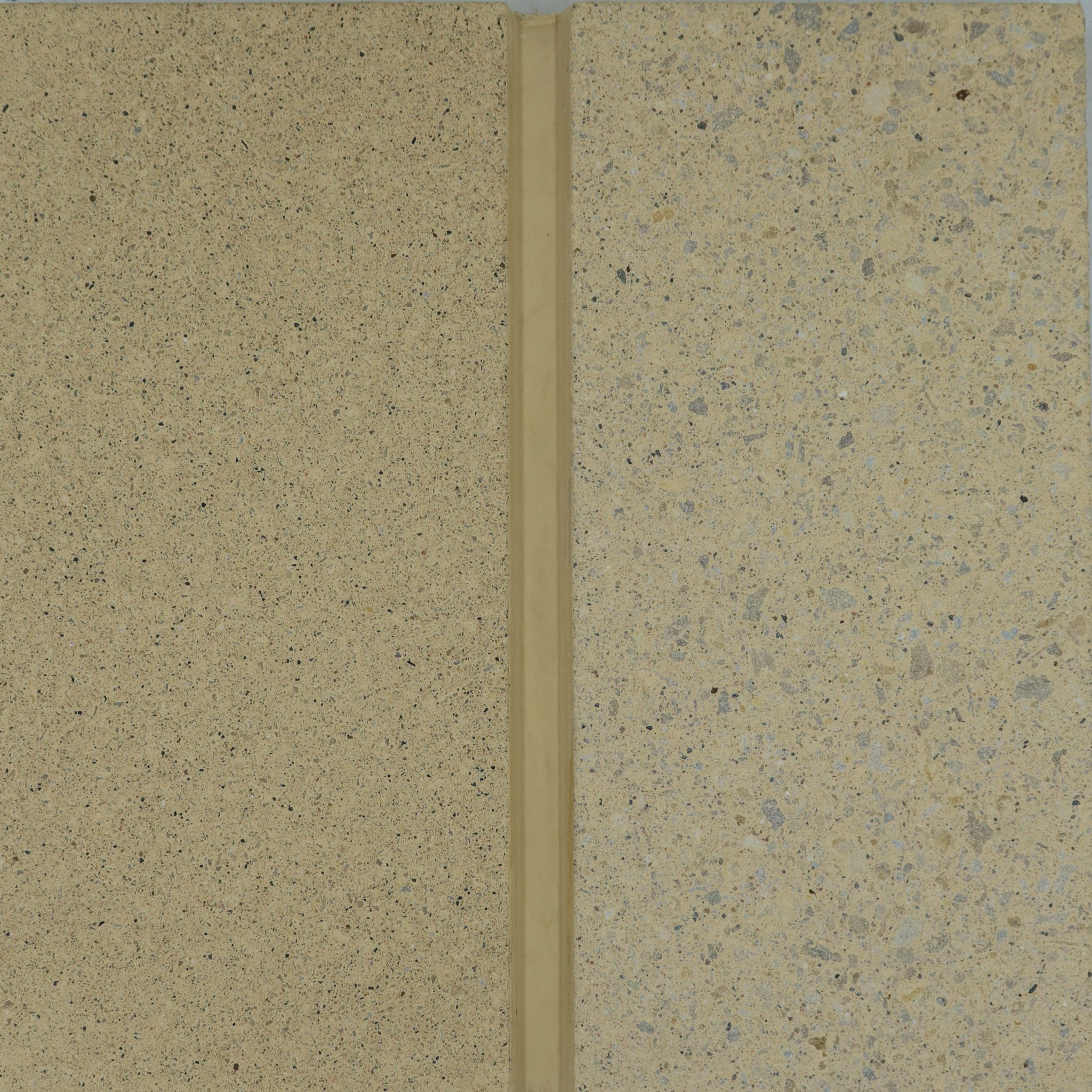

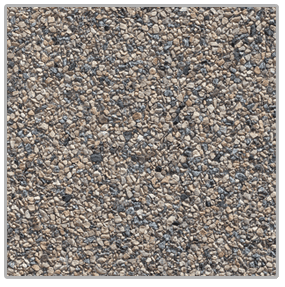

Abrasive Blasted (e.g. sand-blasted)

This process uses a blasting material (commonly sand) to abrade away the surface, exposing the sand and stone. This typically frosts and lightens the surface.

Thin Bricks

Thin brick wall panels create the look of a traditional brick structure but with the cost and time saving benefits of precast. We use natural clay brick products cast into the precast wall panel to achieve this finish.

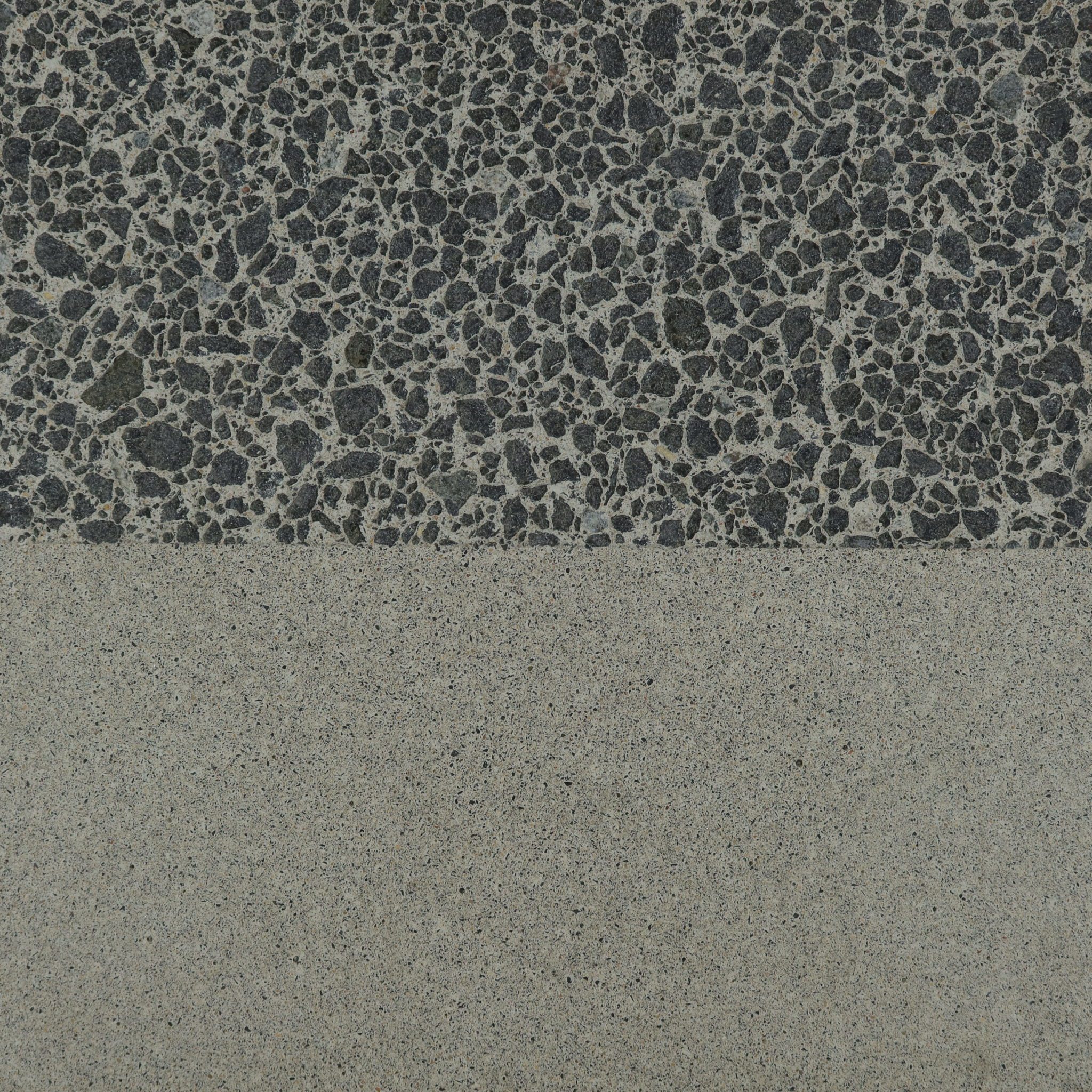

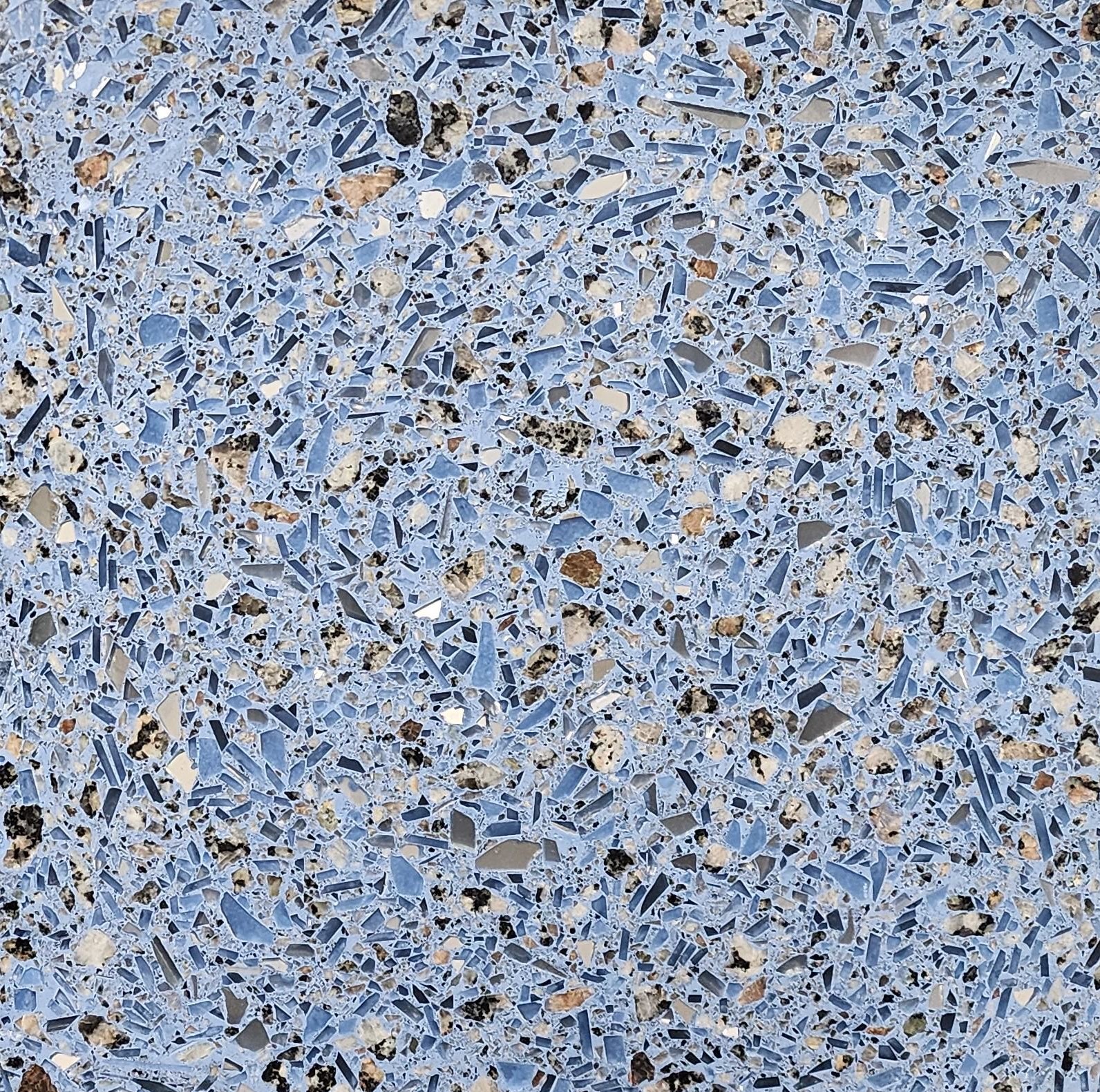

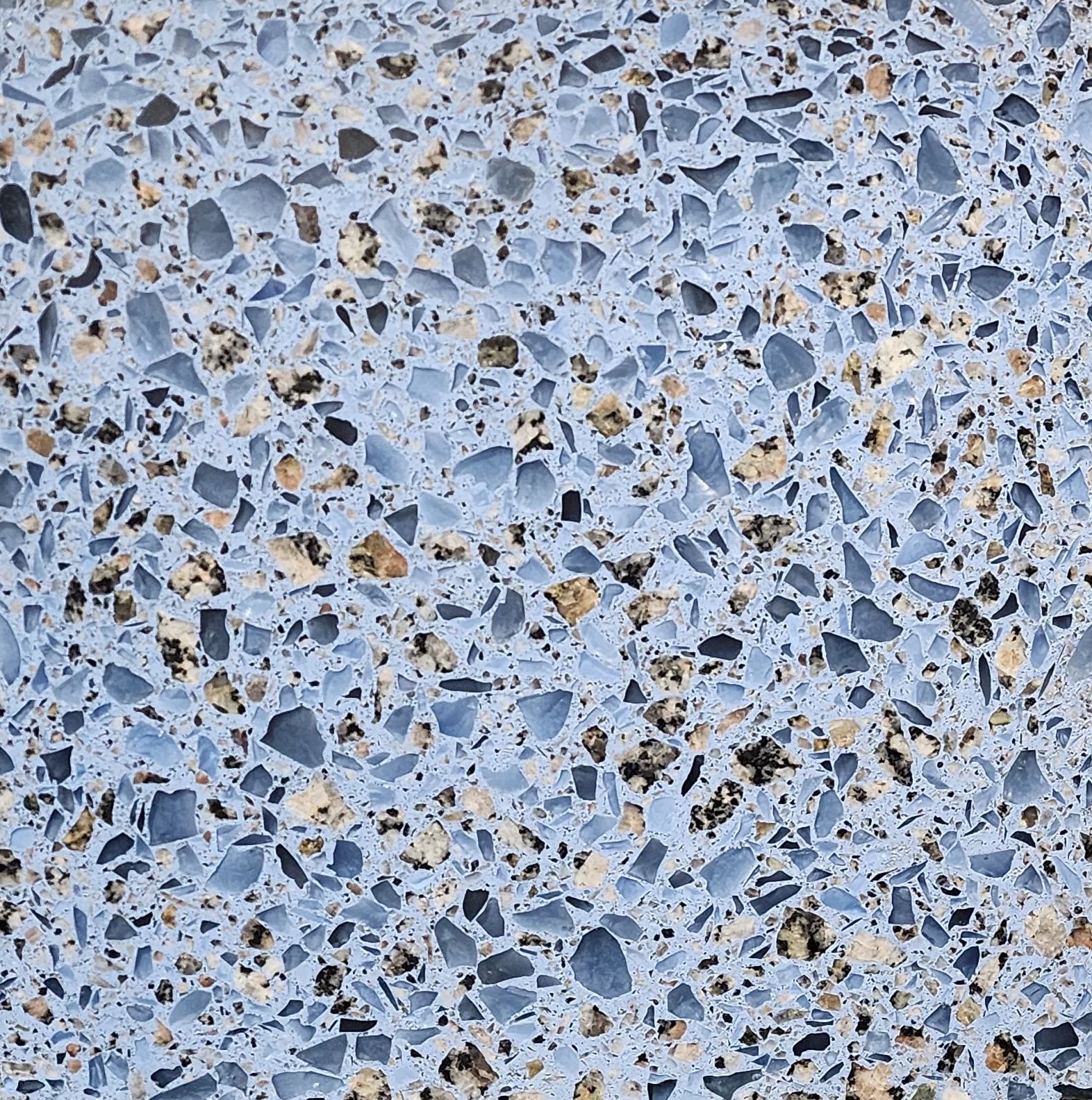

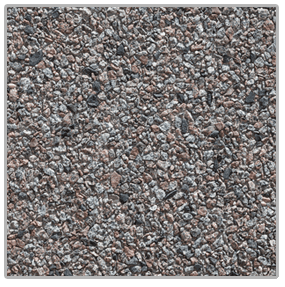

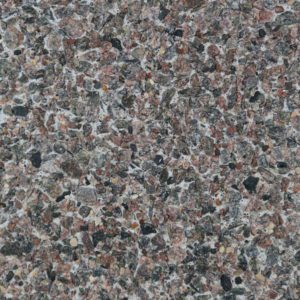

Exposed Aggregate

This process uses a chemical surface retarder which is applied onto the forms prior to casting. The chemical retards the set of the cement so that it may be removed (usually by water blasting) the next day. This results in exposure of the aggregate while preserving its natural beauty and texture.

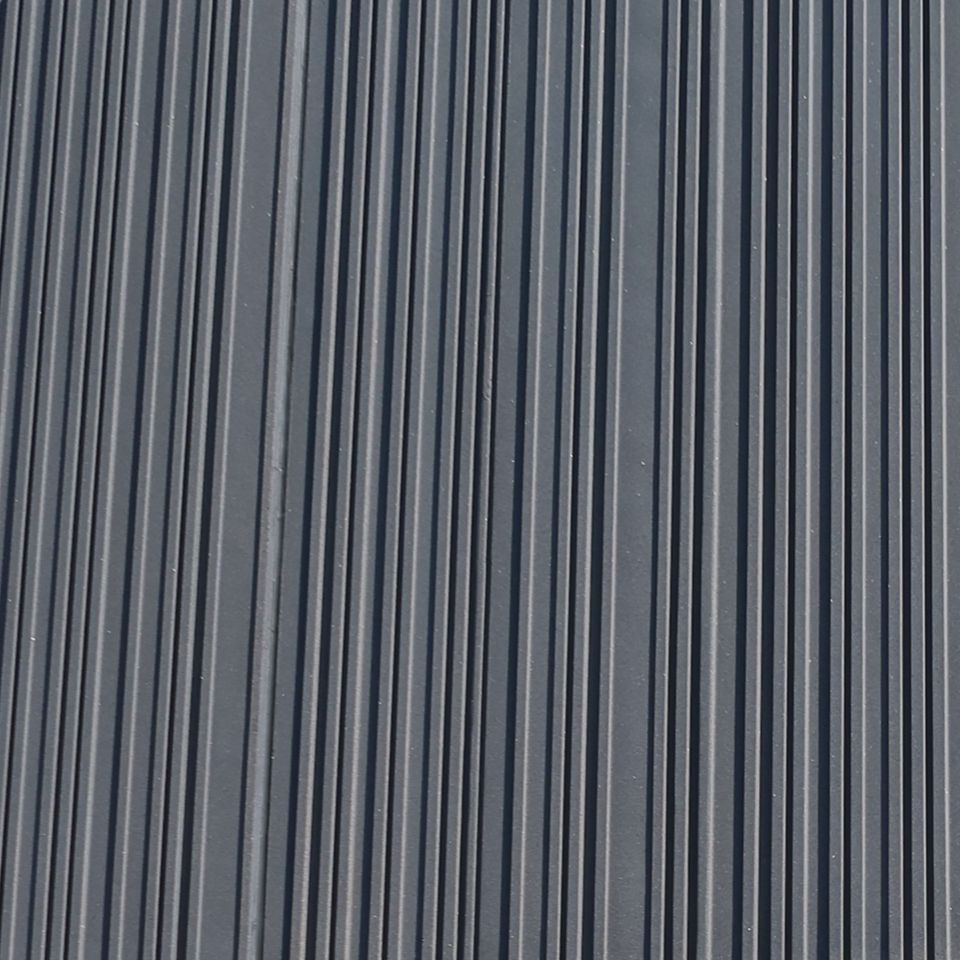

Custom/Form Liners

Since precast concrete is cast into forms, a variety of shapes and details can be accomplished in precast concrete. Formliners can also be used, especially when repetitive patterns or unique textures are needed.

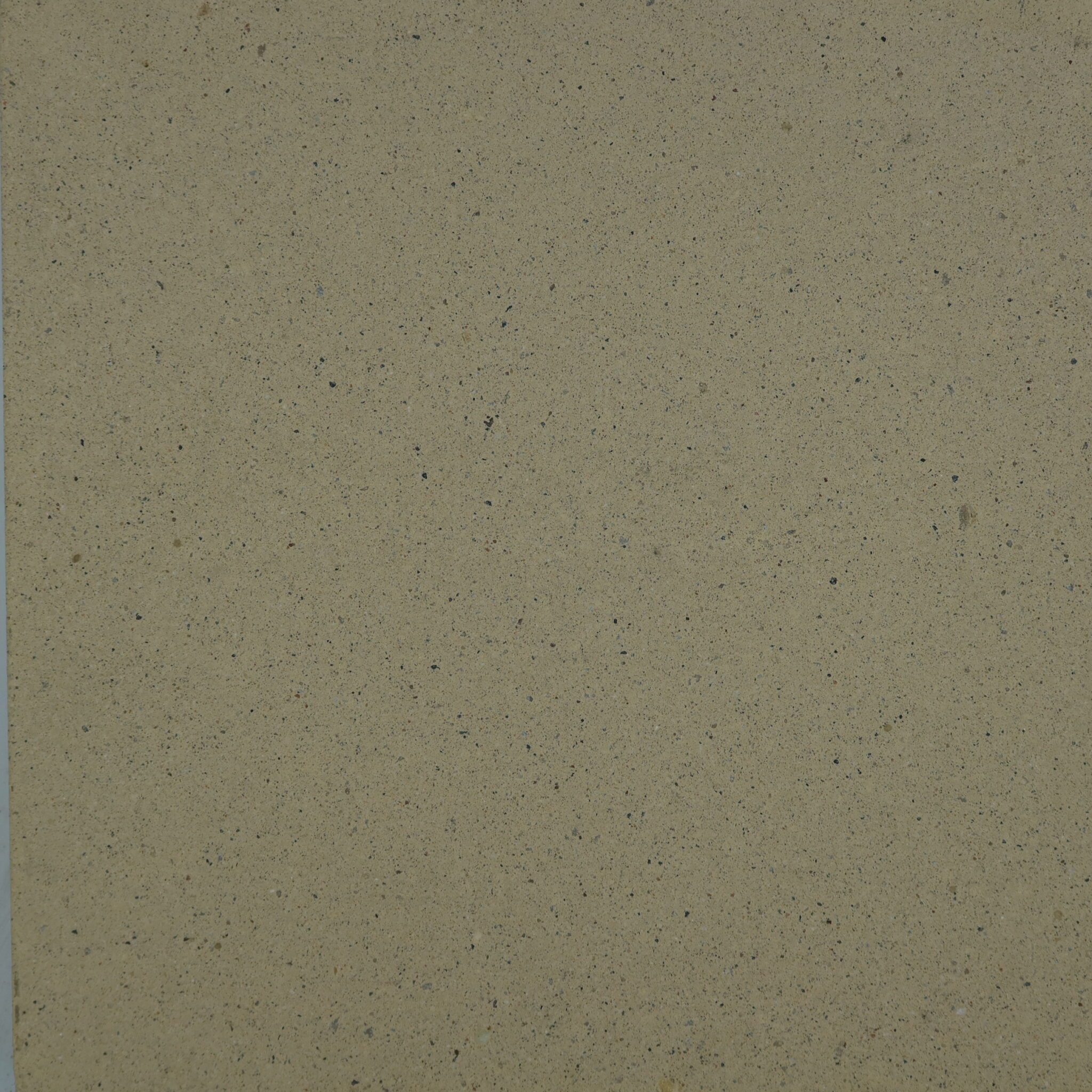

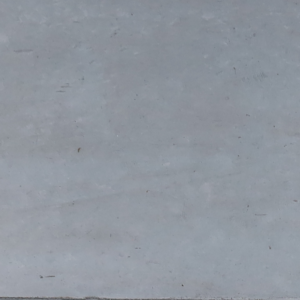

As-Cast (i.e. form finish)

This requires no additional finishing. The surface is left as is, as it comes out of the form.

Hammer Brushed

Uses brushes up to 1000 Grit. This results in a textured finish that has a smooth brushed/polished finish.

Lightly Brushed Brick

Use a series of brushes to add a textured finish to the precast.